In order to check the operation of the hydraulic system, our engineer connected his power pack to the machinery. Once he was satisfied the hydraulic system was operating correctly, the power pack was disconnected and he left the site.

P & R Hydraulics offers an on-site service for customers based in East Anglia because we understand the need to reduce machinery downtime and keep costs to a minimum. Our hydraulic engineer will travel to site, diagnose the problem and continually communicate with the customer regarding any necessary action. Where possible a repair will be performed on-site, however, at times it is necessary for a hydraulic unit to be brought back to our in-house workshop for repair and test.

We will consider site visits further afield - please contact our Service Department with details (01603 424880).

| hydraulic pipework |

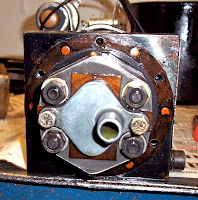

| hydraulic valve and pipework |